Twenty years ago, Andrew Sanderson and a handful of staff set up a card table and laptop inside a shed at RAAF Base Amberley.

Today, Mr Sanderson and 200 staff work at a purpose built, 16,000sq m turbine engine maintenance facility in Bundamba.

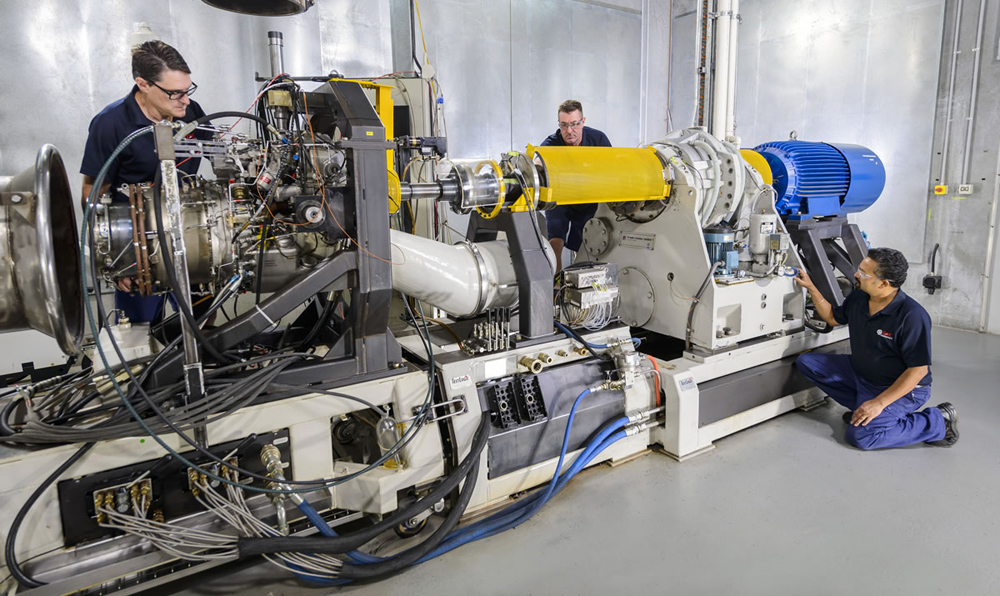

TAE Aerospace is a home-grown, global aerospace player who does maintenance work for engines from the F135 for the F-35 Lightning II, the F414 for the F/A-18 Super Hornet, the F404 for the F/A-18 Classic Hornet and the AGT1500 for the M1A1 Abrams tank.

“When we started we were successful with a contract to help service the F-111,” CEO Mr Sanderson said.

“We employed people out of Amberley and started work.

“I had good support around me and we hoped to become leaders in turbine engines.

“Now we are the largest turbine engine maintenance operator in Australia and we do a lot more today than we ever thought we would be doing 20 years ago.”

TAE Aerospace CEO Andrew Sanderson

This proves to be a year of milestones for TAE Aerospace with the first Australian F-35A engine fan module undergoing routine maintenance, the first time outside the United States.

“The Air Force gives us their broken engines and we give them back a serviceable one and that work is generally all being done from this building here in Ipswich,” Mr Sanderson said.

Ipswich Mayor Teresa Harding commended TAE Aerospace for reaching this milestone, and said that its success had provided a roadmap for other businesses in advanced manufacturing.

“TAE’s story shows what can be achieved when industry knowledge is combined with strong partnerships and a strategic location.

“This is a home-grown company that employs 200 people right here in Ipswich with ingenuity that has led to TAE becoming Australia’s leading turbine engine repairer.” Mayor Harding said.

“I congratulate Andrew and his staff on 20 years in Ipswich and look forward to seeing TAE continue to expand and provide more economic opportunities for the region.”

Minister for Defence Industry Melissa Price said it highlighted the growing capability of Australian defence companies.

“By maintaining and repairing the F-35 engines in Australia, we can get these planes back in the air quicker, while also creating skilled jobs for many Australians,” Minister Price said.

This month Minister for Defence Linda Reynolds praised TAE Aerospace for developing innovative ways to repair parts on the F414 engine that would have previously been thrown away when they failed.

Partner of General Electric International Incorporated (GEII), TAE Aerospace has increased its proportion of deeper maintenance work on F414 engines from 25 per cent to 85 per cent in just five years.

“This is a significant increase in Australian content in only five years and is yet another demonstration of the capabilities that exist in Australia,” Minister Reynolds said.

TAE’s approach has not only reduced costs, it improved engine availability for the Air Force and they are now working to export their services to the US Navy’s F414 engine fleet.

“This is the first time Australian industry has supported the US Navy engine fleet,” Minister Price said.

Mr Sanderson said it was the start of a much bigger relationship in the future.

“We can apply the same capabilities that we have for the Australian Air Force to the US Navy, which is great because they have a heck of a lot more jets than we do,” he said.

The company expanded into working on the Army’s Abrams tanks.

“They also use a turbine engine so it fits into our business,” Mr Sanderson said.

“We also manufacture the chassis that hold the avionics which is liquid cooled.

TAE also does wheels and brakes for customers like Qantas and the Air Force and offer a fire protection systems for aircraft and rescue equipment.

Moving forward Mr Sanderson plan is to focus on what they have built so far and expand each area of the business.

“Each line can be larger,” he said.

“The prospect for growth, now we are in our new building here in the city, will allow us grow all the pieces of it.

“We want to provide more jobs both in technical and administrate roles.

“By the middle of next year we hope to have 20 to 25 roles available.”

Read also:

About TAE Aerospace

At 1 Jet Place, Bundamba is the new site allowing TAE Aerospace to expand quickly and streamline their work.

Any depot work that needs doing on aircraft in the Asia Pacific market, makes its way to Ipswich.

“We are used to being in the city now and it’s good for our people,” Mr Sanderson said.

“It’s close to home and we are close to a train station and also to Ipswich suppliers.”

The Ipswich site is one of 11 around the world, from Alaska to Adelaide.

There are about 350 staff world-wide delivering aerospace maintenance, engineering and manufacturing services for a wide range of customers from Air Forces, Armies and Navies through to aerial agriculture and fire-fighting operators.